IUD

Revolutionize IUD development with our quality by design approach. Leverage in silico release predictions for efficient formulation and faster decision-making.

Issue

Hormonal intrauterine devices (IUD) are designed to function for several years. IUD performance is dictated by the arrangement of polymer and active ingredient, where the particle design can have a significant impact on the release kinetics. When particle network attributes are ignored and treated as a black box, it extends the costs needed for development. This is tied to the lengthy formulation-release testing cycle, where the feedback loop for formulation design relies on months to years of in vitro testing. IUD development doesn’t need to be so difficult.

Common Challenges

- No method to determine porosity and particle properties within the device.

- Limited ways to elucidate the release mechanism and polymer behavior.

- Lengthy development cycles due to long in vitro testing.

- Lacking methods to demonstrate Q3 microstructural equivalence for generic development.

- Difficulties establishing IVIVC and performance assurance for clinical trials.

Solution

We encourage our customers to formulate and manufacture through a quality by design approach, using the internal microstructure arrangement for faster decision making. This includes in silico release prediction based on characterized structures, enabling a rapid exploration of the parameter space.

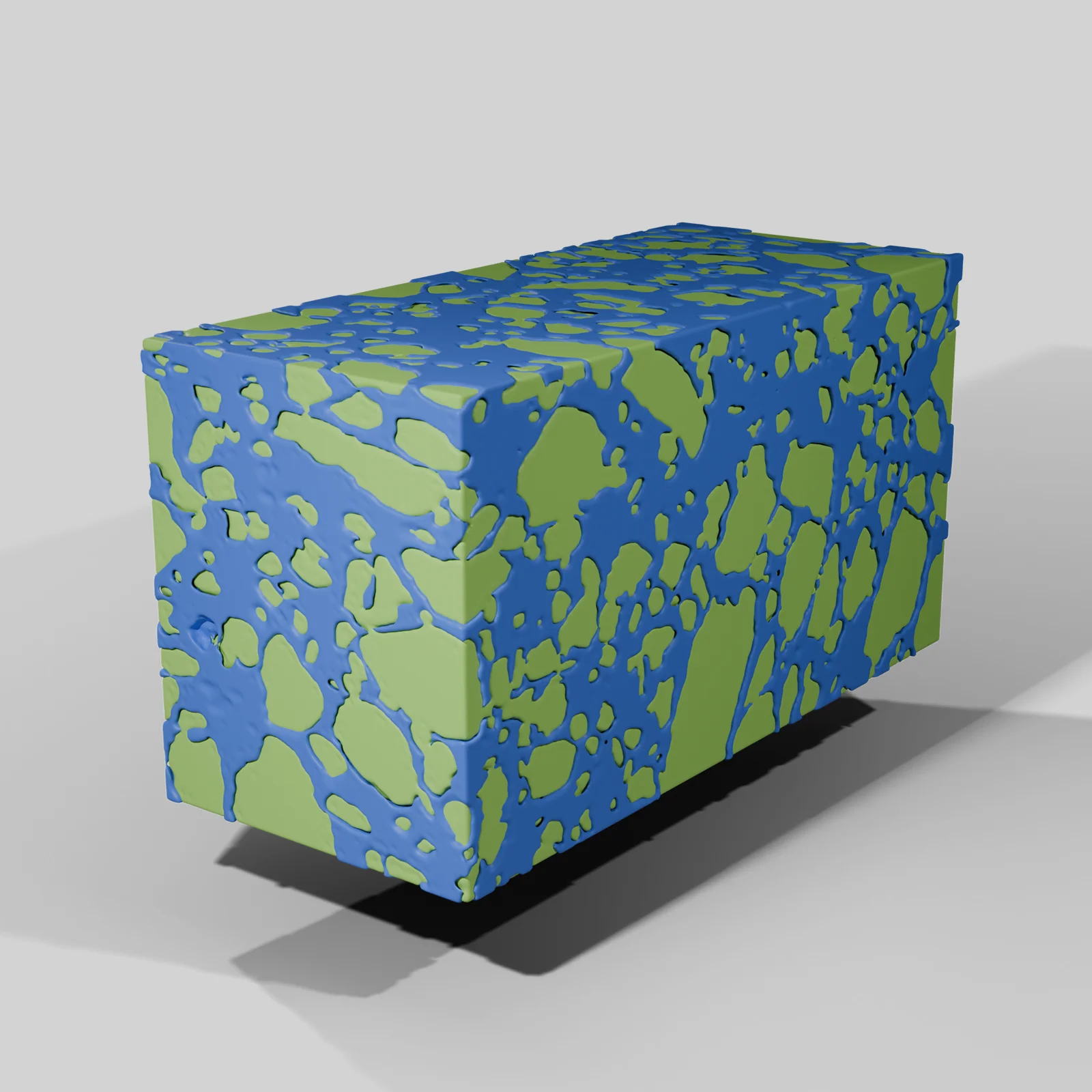

Our IUD analysis uses a correlative approach to study microstructures at multiple resolution scales, ensuring a high level of detail and product representativeness. In silico release prediction based on the real world structures can be run in a matter of days, enabling faster formulation and process selection. Quantified microstructure data and release profiles can be used in both NDA and ANDA filings to demonstrate understanding of the final drug product microstructures and quality. We also study post-partial release implants from in vivo and in vitro studies, enabling quantification of the drug dissolution front, polymer degradation, and other structural changes that can occur. This analysis can offer insights into the impact of the in vivo environment on release and can support the pharmacokinetic data. We support analysis for traditional IUD systems, intravaginal rings, and devices. This workflow can also be applied for animal health contraceptive systems.

Our Approach

- Internal quantification of porosity and API quality attributes.

- Post-release and stability tested sample analysis to evaluate structural changes.

- In silico release prediction to shorten development cycles.

- NDA and ANDA regulatory support.

- Comparative studies of in vivo and in vitro tested products to enable IVIVC.

Formulations

Studied

Transform Your Program with Microstructure Science

Get started with a drug product digital twin.